Patient-Specific Facial Implants

The concept of a ‘custom facial implant’ today is quite different from just a decade or so ago. Historically a custom facial implant was fashioned during surgery using a standard preformed implant or implant material. The surgeon eyed the problem externally and made what he/she felt looked best by hand carving an implant and putting it into what looked like the best place on the facial bones. The surgeon was viewed as a sculptor and an artist whose eye for detail and facial beauty ensured the best possible aesthetic result.

While this is a very romantic view of custom facial implant work, it has many potential aesthetic complications which are reflective of limitations of a true detailed understanding of the patient’s anatomy. Today technology has surpassed the need for much of the guesswork in aesthetic facial implant augmentations. The use of 1.0mm or less slicing of 3D CT scans makes the creation of very detailed anatomic images and models readily available. This unparalleled anatomic insight and the use of computer software has made the designing and manufacture of patient-specific facial implants more exacting with much improved aesthetic outcomes. It is almost true that whatever the patient and the surgeon can imagine, tissue tolerances notwithstanding, is possible to create and surgically implant.

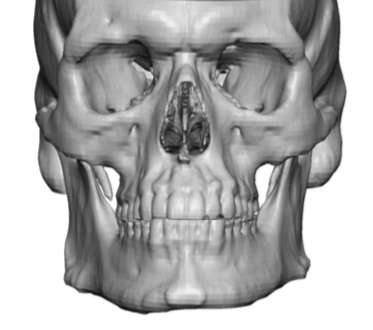

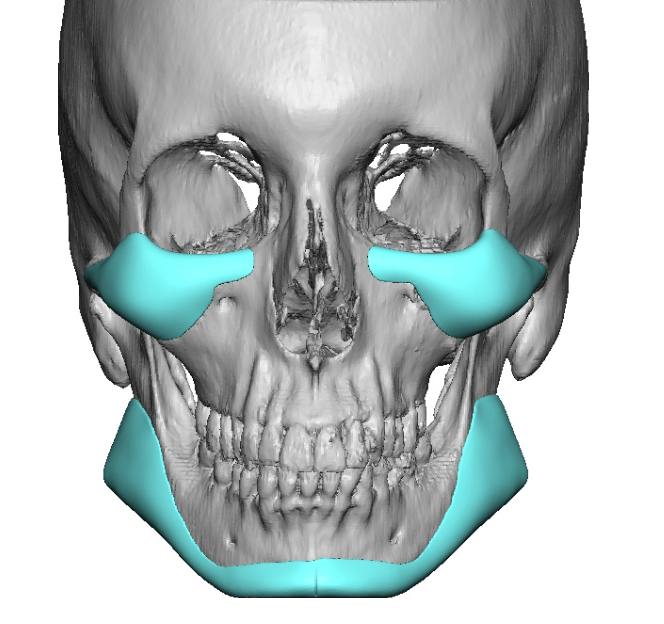

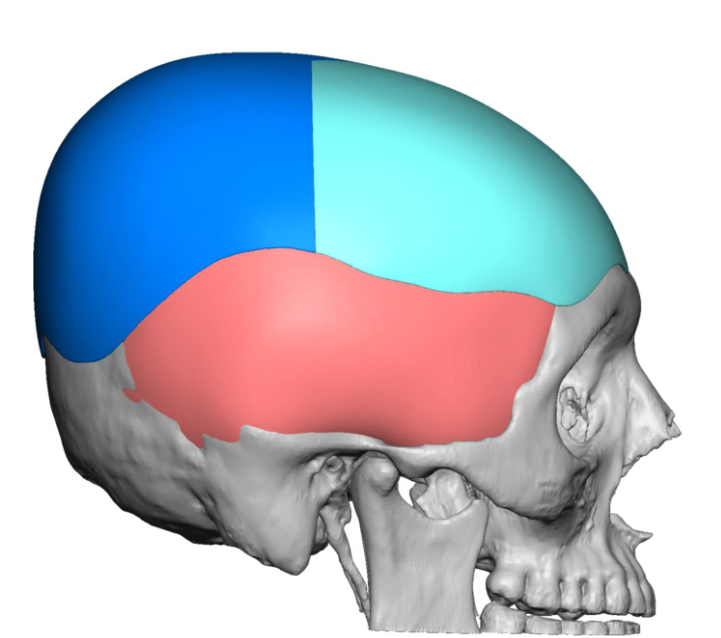

The process begins with the patient obtaining a 3D CT scan of their face. This is typically done at a local imaging center that is geographically convenient for the patient. In some implant cases of just the chin, jaw angles or entire jawline a cone beam or CBCT scan, which is available in some dental offices, can be used. Once the scan is obtained from the patient the first implant design is created by Dr. Eppley. The initial implant design is based on a visual extraction of implant dimensions obtained from prior imaging of the patient’s pictures which has set the patient’s aesthetic target.

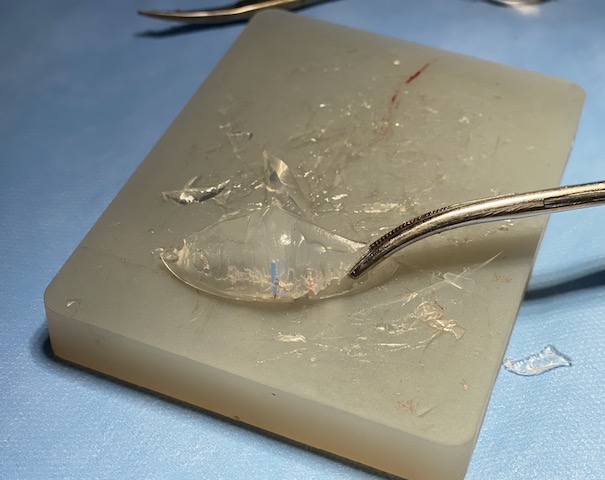

The initial set of implant planning pictures are then sent to the patient for review. Thereafter additional design sessions are done in a virtual setting on a doctor-patient collaborative basis to create the final implant design. Once the design is completed and approved by Dr. Eppley it is then sent for manufacture. Dr. Eppley makes the final decision on all patient implant designs, as he not only has a tremendous experience in thousands of custom facial implant designs, but has the important understanding of how the implant must be surgically placed.

One frequent misunderstanding of the custom implant design process is that it is not an exact science. While making the implant and determining its dimensions is an exact science, knowing what the exact aesthetic outcome will be is not. There is no technology yet available that allows one to know for sure the aesthetic outcomes of any custom implant design. It is not yet possible to take an implant design, put the soft tissue back over it and then see what it looks like. This would be great if it existed and would make the design process much easier but it is simply not yet available. For now it takes an experienced surgeon to translate the computer imaging into an implant design that can come close to the patient’s desired facial augmentative result.

There are several critical time components to the custom facial implant process. Once the process is initiated the minimal length of time until the implant(s) are available for surgery is eight (8) to ten (10) weeks. If a surgery date has been established at the start of the design process, the implant design must be completed thirty (30) days before the surgery date to allow for adequate manufacture, sterilization and shipping time to arrive for the surgery.